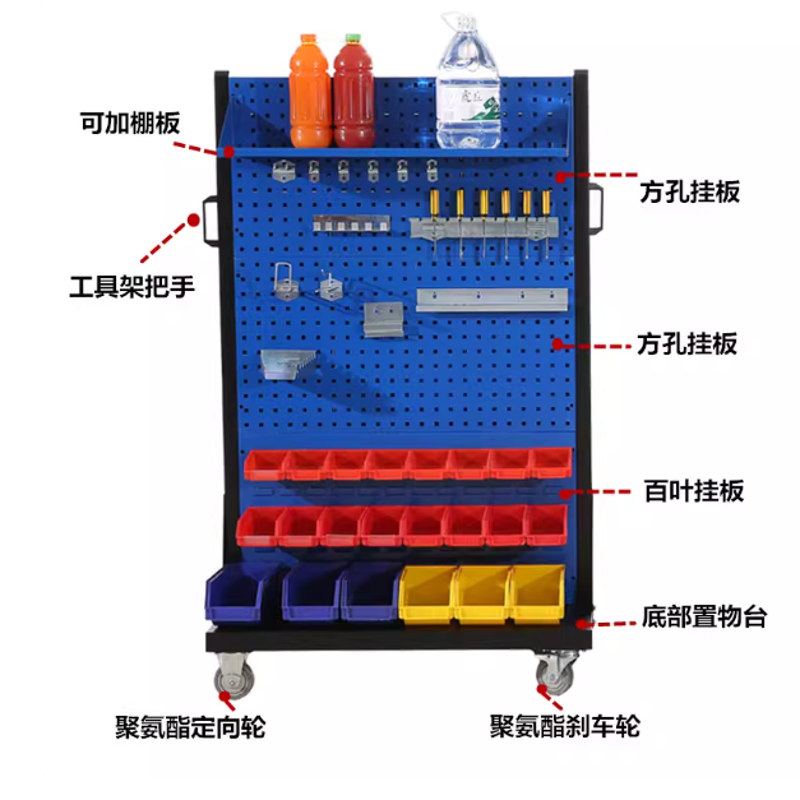

Tool rack, material storage rack, pegboard, square hole hanging board, hooks, hardware tool cart, display rack, double-sided movable.

One-stop solution for tool racks and material organization

Our product range comprises six core products: tool racks, material organizers, pegboards/square hole pegboards, hook accessories, hardware tool carts, and display racks. We cater to the tool and material management needs of workshops, warehouses, repair stations, hardware stores, and other scenarios, providing a full-process service from needs analysis, product selection, customized production to installation and after-sales support. This helps businesses achieve visualized tool management, efficient storage and retrieval, and a neat and orderly environment, thereby improving operational efficiency and space utilization.

I. Preliminary Needs Assessment

To ensure solution suitability, we will conduct four core assessments:

Application Scenario Analysis: Clearly define the usage environment (workshop/warehouse/store/showroom), space dimensions (length × width × height), and installation method (floor-mounted/wall-mounted/mobile).

Tool and Material Characteristics: Determine tool types (wrenches/screwdrivers/pliers/drills, etc.), dimensions, weight, and quantity; material specifications (screws/nuts/small parts, etc.) and packaging.

Access Frequency and Workflow: Differentiate between frequently used tools (high-frequency area) and spare tools (low-frequency area), plan tool retrieval routes, and match workbench locations.

Load-Bearing Capacity and Environmental Requirements: Confirm single-layer load-bearing requirements, rust and corrosion resistance levels (normal/humid/acidic/alkaline environments), and color customization requirements (corporate color/warning color).

II. Core Product Selection and Application Scenarios Matching

| Product Types | Core Application Scenarios | Standard Specifications and Configuration Points |

|---|

| Tool rack (floor-standing) | Centralized tool storage in the workshop, tool management in the repair station, and tool area in the warehouse. | The column height is optional from 1.5-2.5m, and the shelf load capacity is 50-200kg/layer. It can be equipped with square hole pegboards/louvered pegboards, suitable for storing tools and materials together. |

| Material sorting rack (hanging plate type) | Small parts classification, electronic component storage, hardware accessories management | Standard perforated mounting plate + louvered mounting plate combination, compatible with various sizes of parts boxes, supports color-coding to distinguish material categories. |

| Perforated board / square hole pegboard | Wall-mounted tool storage, tool hanging around workbench, store display | Standard dimensions: 900×450mm/1200×600mm, square hole size 10×10mm, hole spacing 28-38mm, thickness 1.0-1.5mm, cold-rolled steel, powder-coated/galvanized surface treatment. |

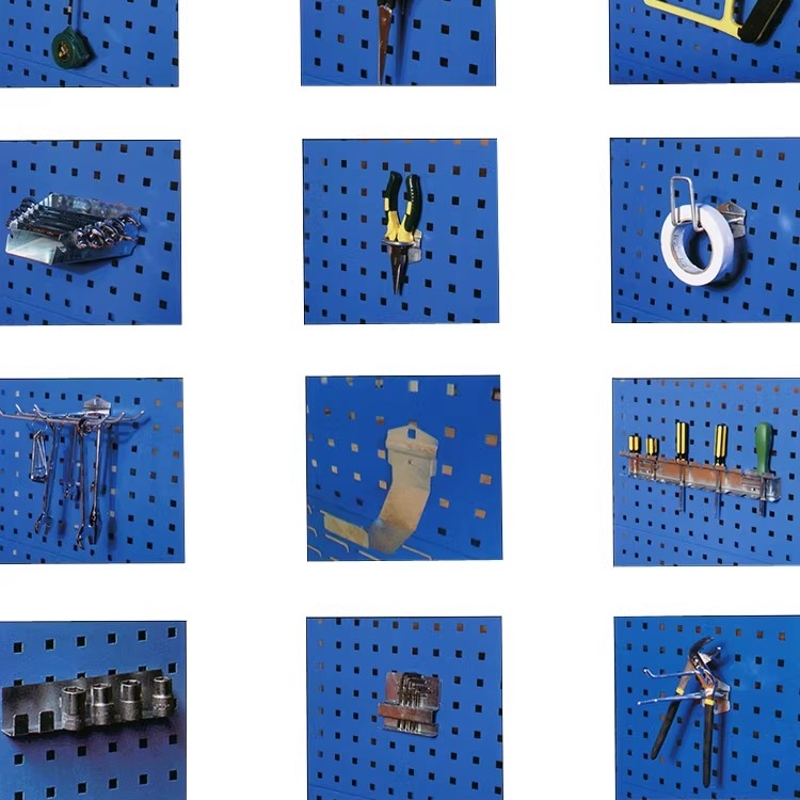

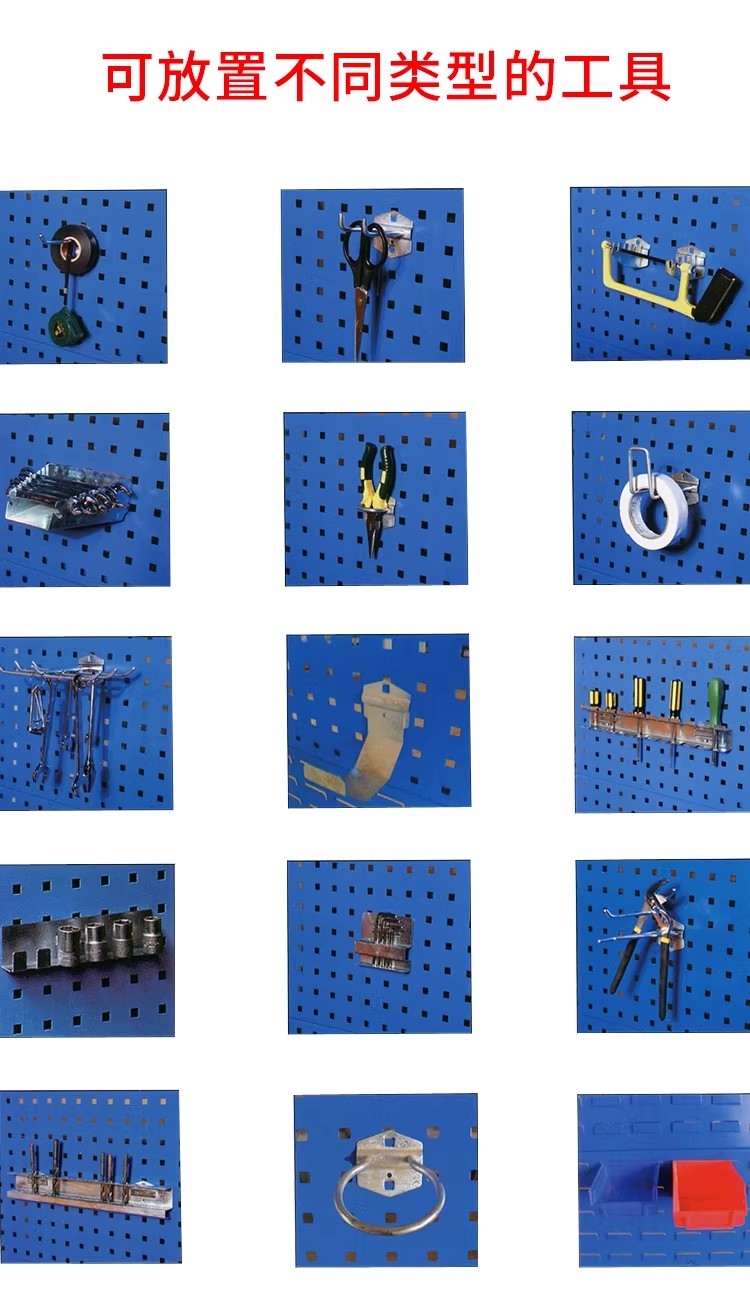

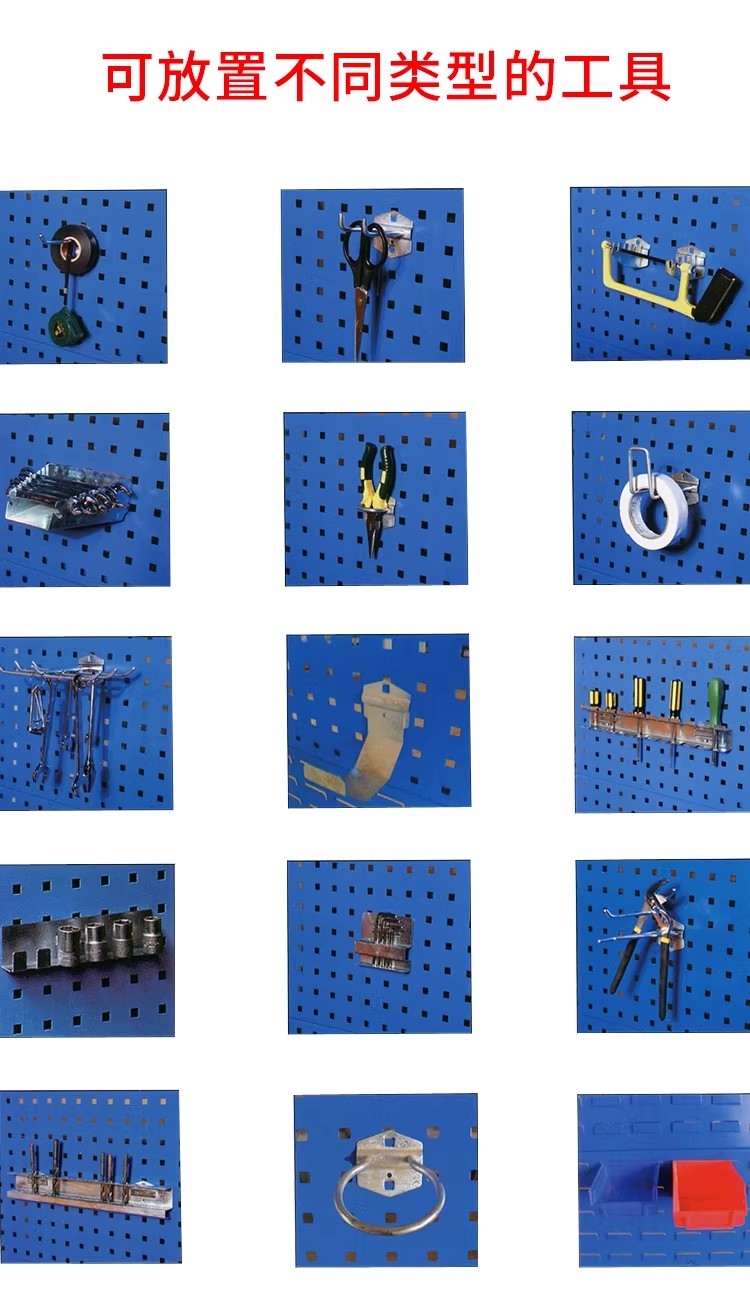

| Hook accessories | Hanging of various tools (wrench/socket/pliers/hammer, etc.) | Includes over 20 specifications such as angled hooks, straight hooks, double hooks, socket racks, and screwdriver holders, with load capacities ranging from 5-50kg. |

| Mobile hardware cart | Maintenance site tool transfer, production line tool delivery, mobile operations | Available in 2-5 tiers, with a load capacity of 100-300kg, equipped with polyurethane silent casters (2 with brakes), and customizable combination of hanging panels and drawers. |

| Display rack (store/showroom) | Hardware store product display, tool brand showroom, exhibition product display | Customizable in size and color, with LED light strips, supports combination of hanging panels and shelves, adaptable to different tool display needs. |

III. Customized Solution Design

As a professional customization supplier, we can provide personalized services based on customers' specific needs:

* **Size Customization:** Custom-made extra-large pegboards (e.g., 2400×1200mm) according to wall dimensions; customized tool rack height according to workbench height; customized hook spacing according to tool length.

* **Structure Customization:**

* **Tool Racks:** Combination of square-hole pegboards and louvered pegboards; three-in-one design of pegboards, shelves, and drawers.

* **Tool Carts:** Single-layer reinforced load-bearing (300kg+); tool carts with power sockets (compatible with power tools); tool carts with lockable drawers (anti-theft for valuable tools).

* **Display Racks:** Display racks with lightboxes; rotating display racks; foldable portable display racks.

Customizable Materials and Surface Treatments:

Materials: Cold-rolled steel (for general environments), stainless steel (for humid environments/food industries), aluminum alloy (for lightweight requirements)

Surface Treatments: Electrostatic powder coating (multiple colors available), galvanizing (rust prevention), chrome plating (aesthetically pleasing and durable)

Customizable Accessory Combinations: Matching dedicated hooks to tool types (e.g., socket racks, wrench hooks), along with parts boxes, dividers, label racks, and other accessories, achieving precise one-item-one-location management.

IV. Quotation and Selection Guidance Process

Submit Requirements: Customers provide basic information such as application scenario, space dimensions, tool list, and load-bearing requirements.

Free Solution Design: 2-3 selection solutions will be provided based on requirements, including layout diagrams, product configuration lists, and space utilization calculations.

Detailed Quotation: A transparent quotation will be provided, covering all costs including main materials, accessories, transportation, installation (if required), and after-sales service, with no hidden costs.

Selection Recommendations: Based on budget and requirements, the most cost-effective solution will be recommended (e.g., a floor-standing tool rack + square hole pegboard combination for commonly used tools in the workshop, and a hardware tool cart for mobile operations).

V. Space Layout Optimization Suggestions

Wall Utilization: Install pegboards/square-hole pegboards on the wall behind the workbench for easy access to frequently used tools, saving workbench space.

Zoned Management:

* High-Frequency Tool Area: Located near the workbench, using hooks for visible access.

* Low-Frequency Tool Area: Stored using tool racks and shelves, with categorized labeling.

* Small Parts Area: Utilizing material organizers, louvered pegboards, and colored parts boxes for easy categorization and identification.

* Combined Mobile and Fixed Storage: Fixed tool racks store frequently used tools, while hardware tool carts are used for on-site operations, achieving an efficient "fixed storage + mobile access" model.

Safety Protection: Anti-slip mats are added to the bottom of tool racks, tool carts are equipped with brakes, and hooks are regularly checked to prevent tools from falling and causing injury.

VI. Installation and After-Sales Service Guarantee

Professional Installation: Wall-mounted products come with installation drawings and expansion screws; floor-standing products support free installation and debugging to ensure stability and safety.

After-Sales Maintenance: We provide a 1-year free warranty and lifetime maintenance service; regular on-site inspections of product status and timely replacement of damaged parts.

Parts Supply: We offer a long-term supply of various hooks, parts boxes, casters, and other accessories to ensure continuous product use.

Training Service: We provide training for operators on tool rack usage, tool classification management, and safe operation to improve tool management efficiency.

Do you need me to generate a draft of a customized tool rack and material organization plan (including layout diagram and detailed quotation) based on your space dimensions, tool list, and budget?

Mail:Lisa@warehouserackfactory.com